Description

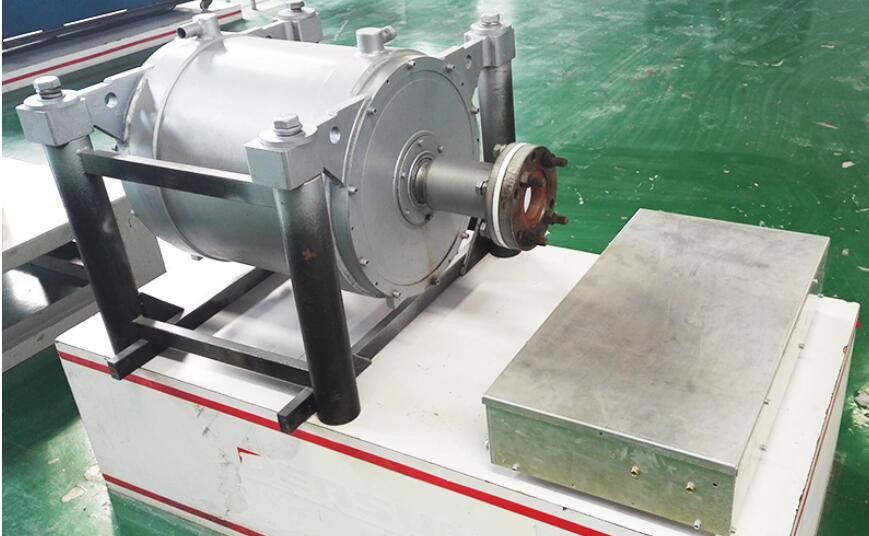

Switched reluctance drive system for pure electric bus The new switched reluctance drive system for pure electric buses adopts a new patented motor structure. Through computer simulation and optimization, the weight of the system is reduced by about 34%, and the peak torque is increased by 20%. The motor controller applies the world's most cutting-edge electronic control technology, with online energy automatic optimization and efficient braking energy feedback control functions. The locked-rotor current and instantaneous start-up impulse current of the new system are reduced by about 50% compared with the original induction motor, and the efficiency in the low-speed zone is greatly improved

Performance characteristics: 1. The starting current is small, only 30% of the rated current is required to reach 1.5 times the rated torque to start, reducing the impact on the battery system and improving the electromagnetic service life; 2. It has high system efficiency in a wide speed range and power range, which is especially suitable for working conditions such as urban buses. Compared with the variable frequency drive system, the system saves more than 25% of energy and increases the cruising range by 30%; 3. High power density, small size, light weight of the system, reducing the load of the whole vehicle; 4. The overload capacity is large, meeting the requirements of electric buses, such as full-load slope starting; 5. Realize the smooth transition of speed control and torque control, ensure the stable output of smooth torque of the electric bus motor, and improve the comfort of passengers; 6. Excellent power generation braking and energy feedback performance, high energy feedback efficiency, effectively improving the cruising range;

Rated Power(kw)

Rated speed

Rated torque

Voltage range

Efficiency

Speed range

Stall

Coefficient

Feeding

efficiency

(r/min)

(N.m)

DC(V )

( % )

(r/min)

( % )

75KW

1000

716.2

450-750

93.8

0~3000

3

20~35

90KW

1000

859.5

450-750

94

0~3000

3

20~35

110KW

1200

875.4

450-750

94.5

0~3000

3

20~35

132KW

1200

1050.5

450-750

94.6

0~3000

2.5

20~35